Temac Slitter Rewinders

Established in 1999, TEMAC Srl engineer and manufacture high quality converting equipment dedicated to plastic film, paper and foil industries. Based near Milan, the heartland of Italy’s extrusion industry, TEMAC manufacture single, double and turret slitter and rewinders equipped with state-of-the-art operation software.

Each slitter is designed in conjunction with the customers requirements, therefore each machine can have unique attributes, tailored to its specific use.

All Temac slitter rewinders can be equipped and adapted to the particular needs of the customer, depending on the material and the various applications related to it.

Our range covers:

- flexible food packaging

- rigid packaging eg preformed food trays

- Plastic and paper food/ drink labels

- Adhesive labels and tape

- Paper – natural or coated

- Hygiene and medical supplies including elastic and laminated films used in surgical masks, drapes and covers

- High performance films, polyester film or laminated polypropylene.

See our catalogue here

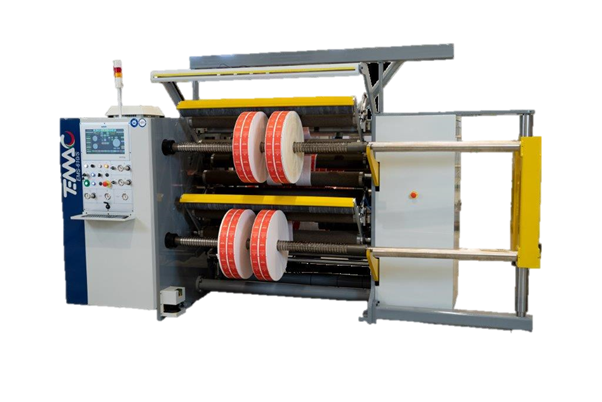

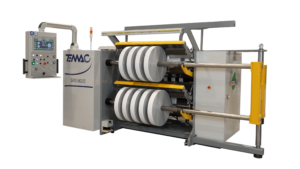

Dual-Shaft Slitter Rewinders

Temac provide many high-quality dual shaft slitters including a ‘TOTAL GREEN’ option in the new SRP 1010 (a completely oil free machine), a low-cost solution in the EMS 610, a mini slitter model in the TMS 840 and a micro slitters with the THS 535.

Temac’s dual shaft slitter range can be useful in several industries including:

- Hot/cold stamping foil

- Special film

- Paper

- Aluminium

- Plastic film

- Laminates

- Coex film

- Flex Materials

With a plethora of options under the renowned Temac name, all bases are covered.

EMS 610– A multi-purpose, low cost option that maintains technical excellence and high quality.

Optimal Industries- Paper, Aluminium, Plastics, Laminates

SRS 962– A traditional slitter that ties simplicity and flexibility with performance.

Optimal Industries- Laminates, Paper, Plastic Film, Coextruded Film, Aluminium Foils

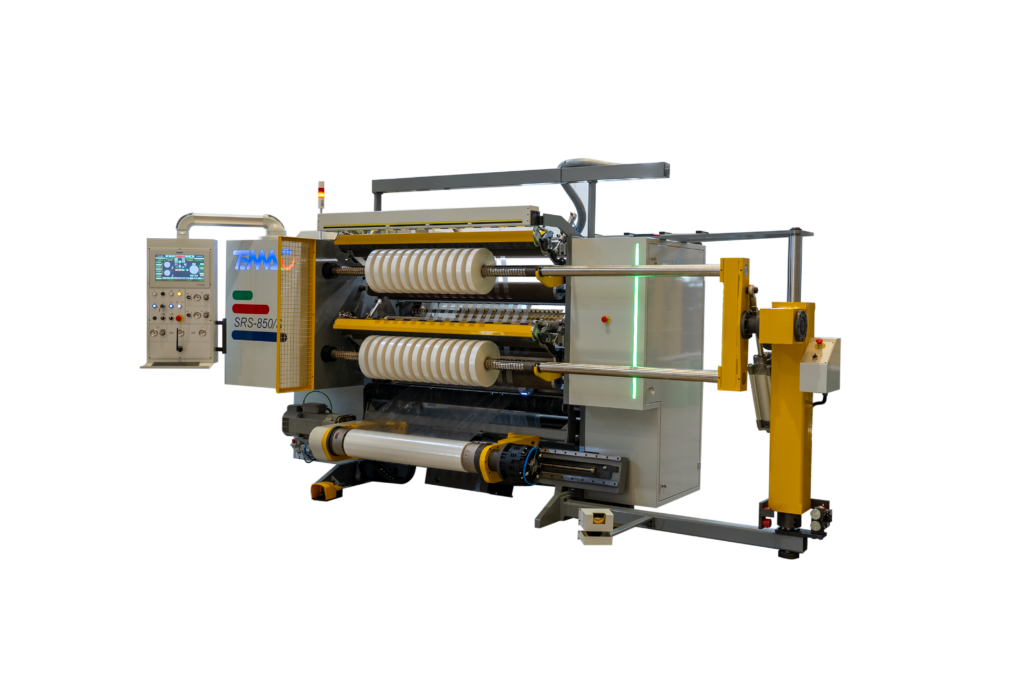

SRS 850– Combines compact design with a single side work front for ease of use.

Optimal Industries- Multiple Flexible Materials Industries

SRS 861– Combines compact design with a single side work front for ease of use.

Optimal Industries- Multiple Flexible Materials Industries

SRP 162– A ‘TOTAL GREEN’ slitter with top web passage, providing economic compatability and energy savings.

Optimal Industries- Paper, Aluminium, Plastic Films, Laminates

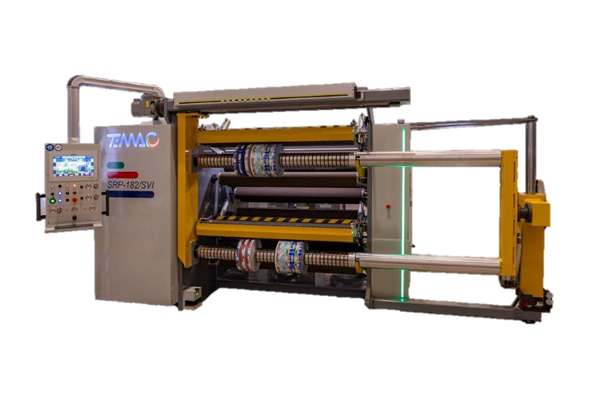

SRP 182– A ‘TOTAL GREEN’ slitter with top web passage, providing economic compatability and energy savings.

Optimal Industries- Paper, Aluminium, Plastic Films, Laminates

SRP 1010– A ‘TOTAL GREEN’ slitter with top web passage, providing economic compatability and energy savings. ‘Close loop’ shot handling guarantees maximum rewind accuracy.

Optimal Industries- Paper, Aluminium, Plastic Films, Laminates

TSW 801– Designed to provide equally high quality performance and adaptability, this slitter can work a wide range of materials whilst guaranteeing user friendly operation.

Optimal Industries- Plastic Film, Laminated Co-extruded Film, Paper, Aluminium

TMS 840– A mini slitter tailored for producing the thinnest films and narrowest webs. It’s precision makes it particularly useful in the labels industry.

Optimal Industries- Plastic Films, Paper, Laminates

THS 535– A micro slitter perfect for high precision cuts. Pivotting wheels and a compact self-supporting frame provide easy manoeuvrability and use.

Optimal Industries- Hot/Cold Foil Stamping, Special Films

Single-Shaft Slitter Rewinder

TSA 1312/ISS:

The new TSA is designed specifically for the automotive industry and can work with unwoven insulating material. This one-of-a-kind slitter can unwind reels over 2 meters wide and up to 1300mm in diameter, and rewind narrow bands up to 1200mm in diameter.

Turret Slitter Rewinders

Capable of handling long running multi-set orders and short lengths with many changeovers, Temac turret slitters reduce downtime, increasing productive efficiency.

TTS 160/180– TTS series machines join the best of the flexibility to extremely high performance, supporting the rewinding shaft during all working fases, including the revolving.

Optimal Industries- Plastic Film, Coextruded Film, Paper, Aluminium Foil

ETS 160– An innovative design to bring flexibility and automation at a strong performance to price ratio.

Optimal Industries-

Unloading Side Forks

SF 12: Manual unloading system.

SF 14: Pneumatic system to lower reels to a desired unloading height.

SF 16: Electrical system to lower reels to a desired unloading height.

SF 18: Electrical system to lower reels to a desired unloading height with the added benefit of reel ejection.

SF 20: Motorised version of the SF18 model

SF 22: Automated side fork system which matches the rotation of shafts, the motorised lowering of reels to the desired level and the motorised ejection of reels.