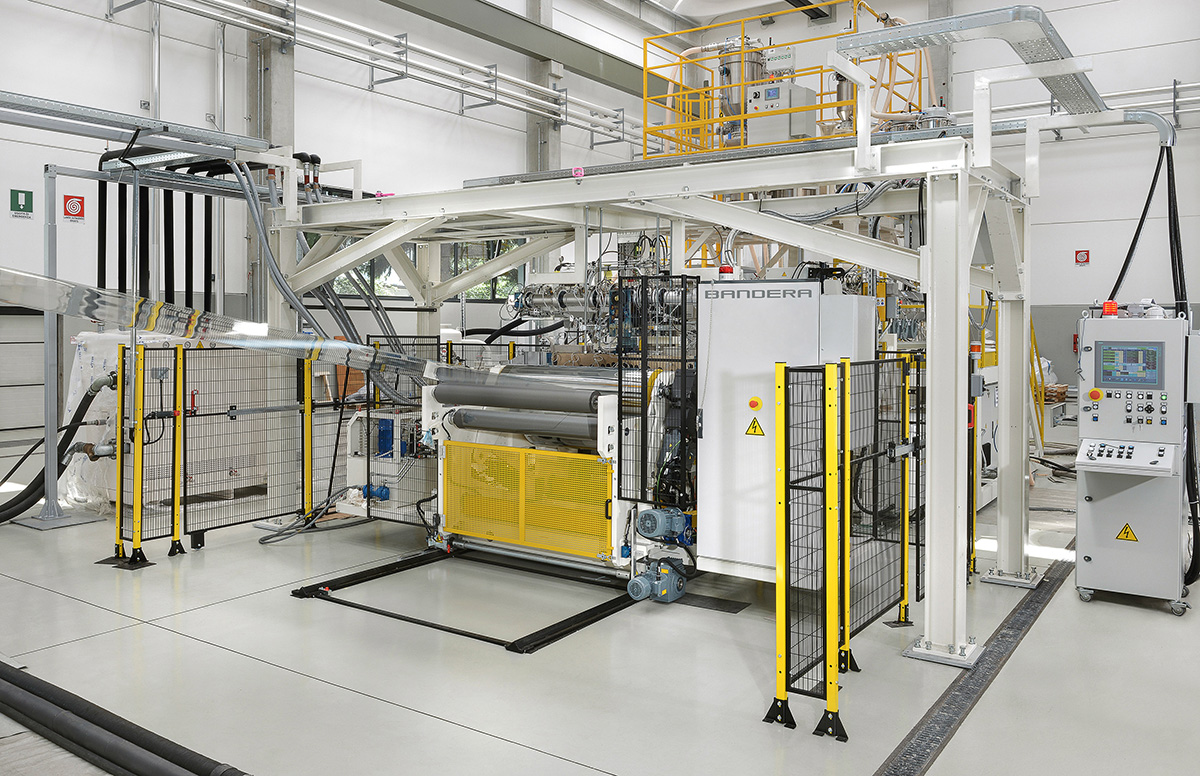

A Manchester based manufacturer of world renowned, thermoformed blister packaging has invested in a Bandera multi-layer PET rigid film extrusion line, supplied by UK Extrusion Ltd. the exclusive suppliers of Bandera products in the UK.

Mister Blister, have been steadily increasing their markets for innovative, blister packaging products. Their unique range of patented tamper proof blister packs are supplied to product manufacturers worldwide.

The purchase of this new rigid film extrusion line is an example of Mister Blister’s commitment to invest in the latest machinery in order to provide their customers with top quality products. Mister Blister Managing Director, Gary Briscoe says “I carried out in depth research before selecting the Bandera line. People within the industry, whose opinions I value, all recommended the Italian manufacturer. I was further convinced by the fact that there are already 12 lines operating within UK manufacturing and an established support network. This is particularly important in a project of this magnitude. From my first meeting with Bandera I have been impressed by their flexibility and eagerness to ensure Mister Blister get the line and outputs we require. It is clear that they see themselves as long term partners of our brand and will support us totally.”

He goes on to explain “We will be working on an average output in the region of 660 kg/hr and expect to produce 2000 tonnes of material per annum. The majority of this material will be for our own production, but we will be selling small orders of several popular widths and microns of sheet from stock.”

Steve Trainor of UK Extrusion Ltd gets down to the technical details of the range “The Bandera PET Rigid Film lines for thermoformed packaging offer maximum flexibility by processing all packaging raw materials. We find them robust and well-engineered, they provide Single Screw Extruders and/or HVTSE co-rotating Twin Screw Extruders (no requirement for drying of raw materials) with the option of the inclusion of mineral fillers (pellets/powder). Packaging manufacturers can select single or multi-manifold flat extrusion die (auto or manual) with internal deckling systems. They are also able to specify from a wide range of winding systems, with varying degrees of automation. I totally agree with Gary, Bandera are so refreshing in their flexible attitude towards supporting their customers and ensuring they get the machinery best suited to their needs.”