Screen Changers

BD Plast has been dedicated to the production and sale of screen changers for polymer extrusion lines since 1986. Our Manual, Semi-Automatic & Fully Automatic screen changers are designed to ensure maximum performance for every extrusion process.

The frequency of screen replacement is vital in achieving the highest degree of cleanliness of polymers. The different ways to replace them and the type of machine used for this activity affect not only the quality, but also the rapidity and cost of the process.

Our range is suitable for the production of:

- Blown or Cast films

- Flat sheet

- Pipes and profiles

- Cable coating

- Pelletising from polymerisation

- Masterbatch and compound pelletising

- Blow and injection moulding

- Adhesives (hot melt)

You can download our full brochure here

Watch our video here

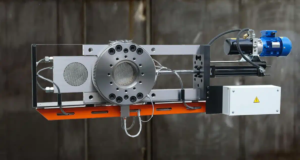

BDL Lever Type Screen Changers

Simple and reliable, the manual BDL screen changers offer the opportunity to improve performance, at minimal cost, especially on small and medium size extrusion and coextrusion lines. Available with filtering areas from Ø 20 to Ø 120 mm, units are equipped with a self-activating sealing system that allows a safe and leakproof use, up to 800 bar working pressure. The actuation lever, manoeuvrable on three sides ensures a quick movement of the sliding plate.

Download the datasheet BDL Lever type datasheet

BDLG ratchet type Screen Changers

Available with filtering areas from Ø 45 to Ø 250 mm, represents a high-quality choice among the manually operated screen changer.

Download the Datasheet BDLG ratchet type data sheet

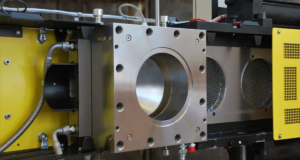

BDO FT Hydraulic Screen Changers

Maximum productivity and customisation to meet the most specific needs. These screen changers operate in combination with a quick change hydraulic power unit allowing the replacement of the filtering media while the extruder is running. Available with filtering masses from Ø 45 to Ø 160 mm. The units are equipped with a cable channel in the bottom that conveys the power cables and thermocouples in a junction box located next to the hydraulic cylinder. This prevents dangerous overheating of the electrical system, ensuring maximum reliability.

Download the Datasheet BDOft data sheet

BDP manually operated hydraulic Screen Changers

These represent the hydraulic evolution of the manual screen changers and are suitable for the processing of highly sensitive polymers due to the specific temperature control of each filter holder. If necessary, for space or placement reasons, the manual pump can be mounted separately. Available with filtering masses from Ø 45 to Ø 160 mm they are equipped with a cable channel in the bottom that conveys the power cables and thermocouples in a junction box, located next to the hydraulic cylinder. This prevents dangerous overheating of the electrical system, ensuring maximum reliability.

Download the Datasheet BDP hydraulic data sheet

BDO FQ Hydraulic Screen Changers

Designed for high production or recycling extrusion lines. The high reliability and durability testify to the quality of this product, which meets diverse needs, with excellent results even in the most difficult and challenging situations. Available with filtering areas from Ø 180 to Ø 450 mm.

Download Datasheet BDOfq data sheet

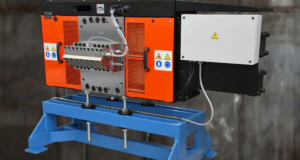

BDOx2 Continuous Flow Hydraulic Screen Changers

A perfect flow continuity even at high working pressure.

With the innovative continuous flow screen changers BDO x 2, the construction complexity is reduced to a minimum and the material quality is guaranteed. The new sealing system allows its use also on extrusion lines working with very high-pressure levels. A simple and effective sealing system with interchangeable components allows even complex maintenance at the customer site, minimizing downtime and costs.

Download the Datasheet BDOX2 continuous data sheet