Complete extrusion solutions for 1–11 layer films, rigid sheets, geomembranes, and recycling or lab-scale R&D applications.

Downstream equipment including loss in weight dosing, gauging, measurement, dehumidifying drying, material handling and line upgrades.

A full range of engineering services with UK-based engineers, including installation, commissioning, preventative maintenance, spares, repairs and operator training.

About us

Experts in

Extrusion Technology

At UK Extrusion, we supply industry-leading extrusion machinery and equipment to plastic processors across the UK and Ireland. As trusted partners of world-renowned manufacturers, we provide high-performance solutions for blown film, sheet extrusion, recycling, and more.

With UK-based engineers, we offer installation, training, maintenance, and 24/7 support to keep your production running smoothly. Whether you need a complete extrusion line or expert engineering support, we’re here to help.

Our products

Innovative Machinery for

Every Stage of Extrusion

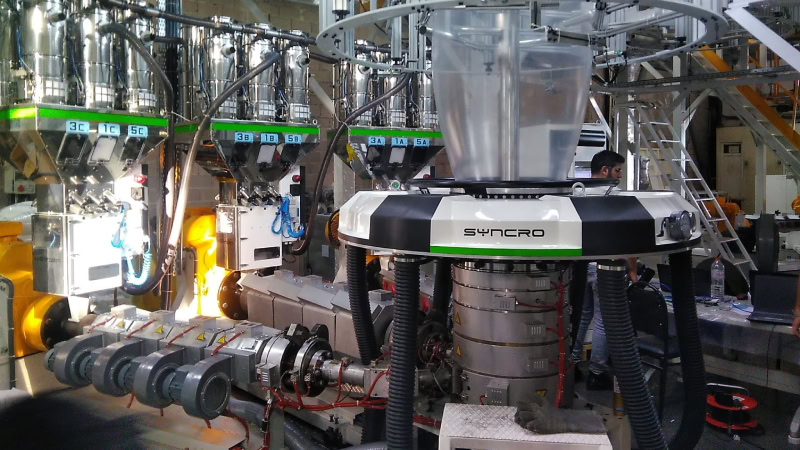

We supply a wide range of extrusion, recycling, and ancillary machinery for plastics manufacturers across the UK and Ireland. Our product range includes blown film and sheet extrusion lines, pilot and benchtop systems, screen changers, repelletisers, laser filters, slitter rewinders, and material handling solutions—all sourced from leading global brands and backed by expert local support.

High-performance film lines engineered for clarity, strength, and multi-layer precision.

Reliable systems for producing thermoformable sheet with tight dimensional control.

Flexible small-scale lines for R&D, testing, and material development.

Essential hardware and upgrades to optimise performance across your extrusion setup.

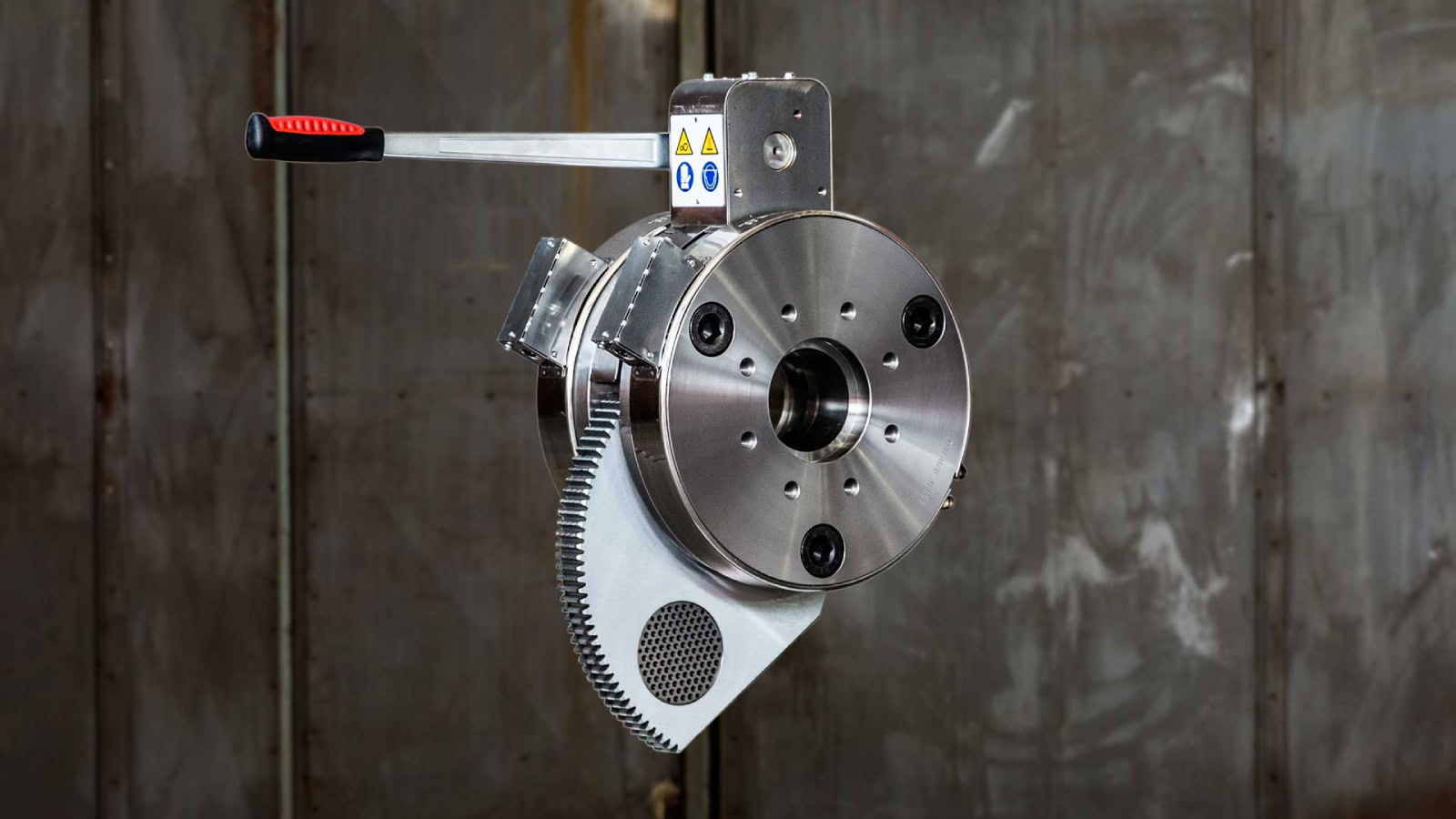

Durable filtration units for consistent melt quality and uninterrupted production.

Advanced systems for converting plastic waste into high-quality reusable pellets.

Inline tools for real-time monitoring of thickness, layers, and surface quality.

Modular equipment for efficient conveying, accurate dosing, and polymer drying.

Custom-engineered systems for safe and efficient transfer of powder and PVC materials.

Precision micro-perforated discs for high-efficiency melt filtration in recycling lines.

Versatile slitting solutions for flexible films, paper, labels, and technical materials.

Containerised treatment systems for recycling wash water and ensuring compliant discharge.

Our Services

Expert Support for

Your Extrusion Operations

At UK Extrusion, we provide end-to-end engineering services to support your extrusion and recycling operations—from initial setup to long-term optimisation. Our experienced, UK-based team offers everything from installation and commissioning to preventative maintenance, factory assessments, and spare parts supply.

Whether you’re moving machinery, upgrading existing lines, or need urgent repairs, we’re here to keep your production running smoothly and efficiently—24/7, 365 days a year.

Industry-Leading Manufacturers

Our Partners

We work with leading global manufacturers to bring the latest extrusion, recycling, and ancillary equipment to the UK and Ireland. Our partnerships ensure access to cutting-edge technology that enhances efficiency, quality, and sustainability in plastic processing.

Our News

latest news

Explore our latest updates, including company news, industry insights and new technology from our partners.

Meet us at INTERPLAS this June

The UK Extrusion team are delighted to be exhibiting at the UK's number one event…

Plastics Industry Award 2025 WINNERS

We are thrilled to win the PIA 2025 award for Sustainable Extrusion Technology. Our project…

Plastics Live! November 26 – 27

Join us in Dublin for the first ever trade fair dedicated to the Irish plastics…

Testimonials

our clients say

My feedback is excellent for UK Extrusion, all the UK Extrusion Team is very helpful, and exceeding world class level of customer satisfaction. I collaborated the most with Stefano and I can only be grateful for his great support on various projects. But I would not nominate only one person, all your team is excellent.

Anonymouson customer request

We originally purchased the Plasmac ALPHA XS granulating machine to recycle and reuse the waste plastic film and side trims from blown film extrusion lines. My team installed the ALPHA XS and the commissioning & training was carried out by UK Extrusion. Since purchasing the ALPHA XS our waste has decreased significantly and the quality of pellet created from XS machine is exceptionally good. The back up from the sales and spare parts teams are also outstanding and I would have no hesitation in using UK Extrusion for any future projects. We hope to purchase another ALPHA XS machine in the next few months to add to our recycling portfolio.

Steve WhiteEngineering Manager, Alfaplas UK

We purchased two benchtop extrusion lines through UK extrusion. We highlighted that our main challenge would be getting both pieces of equipment physically into our small lab. UK Extrusion went above and beyond with helping us with this and coordinated all the logistics involved including the machine movers. Having these pieces of equipment has allowed us to take many processes (that we would have previously outsourced) in-house and hence accelerate our R&D. They’ve also been on hand to help with any technical challenges we’ve encountered since machine installation and connected us to a network of many other extrusion specialists relevant to our field.

Anonymouson customer request

We have recently installed a blown multilayer co-ex blown film line. The project was complex and challenging and required expert advice and understanding of our needs from the outset. UK Extrusion together with manufacturer Bandera worked tirelessly and seamlessly from start to finish and beyond, to ensure our goals were achieved. The level of support was unparalleled. UK Extrusion provide an exceptional service in the UK that no-one else in Blown Film offers. One of the reasons we chose UK Extrusion is that not only are they UK based which makes communication much easier, but they have UK based engineers to support installations, commissioning, training and most importantly continued service.

Josh SalmonDirector, Elite Plastics Ltd

We purchased a Plasmac Alpha 60Eco which was delivered and installed in April 2020, under far from ‘normal’ circumstances due to the Covid19 pandemic. UK Extrusion were able to continue with the installation and commissioning whilst adhering to social distancing requirements. This machine allows us to reclaim production waste from the production of our Silawrap Net Replacement Film, providing not only savings in raw materials, but also preventing this waste from ending up in landfill.

Robbie KehoePlant Manager, Signode Packaging Ireland Ltd t/a Crop Packaging Systems

Our relationship with UK Extrusion goes back several years. We originally purchased a Plasmac Alpha 60HC to utilise our production waste by reclaiming and pelletising our start-up waste, including flake product and coiled films. . The level of service we continue to receive from UK Extrusion makes Bond-a-Band feel that our custom is truly valued and that is worth a lot.

Jonathan HeatonManaging Director, Bond-A-Band Transmissions Ltd

We had the pleasure of working with UK Extrusion on our recent co-ex extrusion line refurbishment project, and we couldn’t be more satisfied with the results. From the initial planning stages through to final delivery, their team demonstrated exceptional technical expertise, professionalism, and a commitment to quality. They approached every challenge with innovative thinking, ensuring the project was completed on time and within budget while maintaining the highest safety and compliance standards. Communication throughout was clear, consistent, and proactive, which gave us complete confidence in their work. We’re incredibly grateful for their contribution and would highly recommend UK Extrusion to anyone seeking a dependable and forward-thinking engineering partner.

David MillarManaging Director, Aintree Plastics